CASES

LED lamps

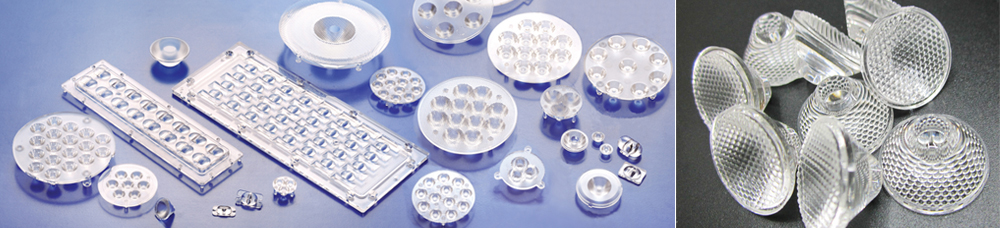

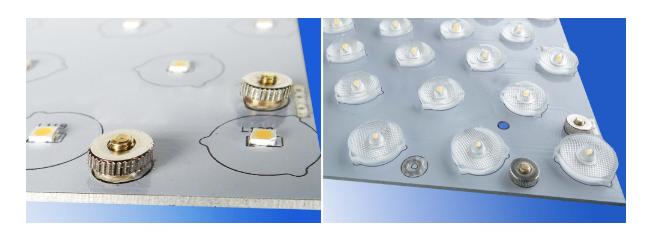

LED lamps are widely used due to their advantages of energy saving, low voltage, fast response speed and low cost. The core component of the LED lamp-the backlight light bar, is to weld the LED lamp beads to the aluminum substrate or PCB board, and then cover the PC or PMMA lens on the lamp beads to make the light emission more uniform. Today we are talking about the application of UV glue, which is mainly used for LED lenses to stick aluminum substrates, and has become a special glue for LED lenses.

In the past, most manufacturers used single-component epoxy adhesive to bond lenses. The disadvantage is that epoxy adhesive needs to be stored at low temperature, which is inconvenient for storage and transportation. The curing time of epoxy adhesive also affects the production efficiency. The use of UV glue for LED lenses effectively solves these shortcomings, fast curing, easy storage and transportation.

Operation process of LED lens sticking to aluminum substrate:

1. Prepare materials: LED lens, aluminum substrate, UV glue;

2. Apply glue to the dispenser;

3. Ultraviolet irradiation through a UV furnace;

4. Quickly cure the finished product;

5. Carry out QC testing;

6. Finished product packaging;

7. The product is out of stock.