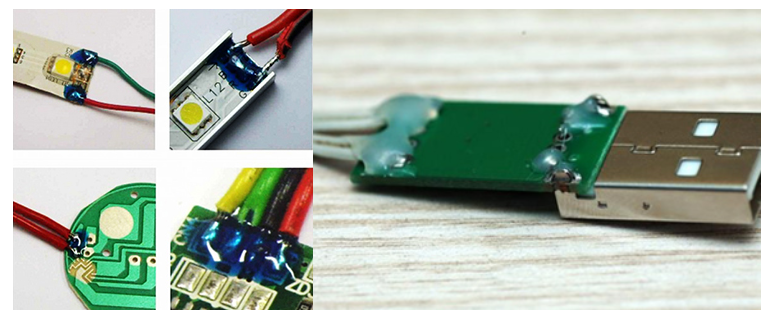

CASES

Protection of solder joints in the electronics industry

Solder joint protection UV glue, with advantages of high viscosity, high toughness, good ductility, etc., effectively protect the solder joints on the circuit board to prevent short circuit, enhance the tensile strength of the upper solder joint, enhance the bonding strength of the solder joint and the substrate, electrical performance excellent.

typical application:

Used for bonding, sealing, insulating, fixing and soldering point protection of electronic components, inductors, capacitors, circuit boards, cables, data lines, connectors and other products.

Application advantages:

Solder joint protection UV glue is a one-component ultraviolet curing resin with high viscosity, high toughness, good ductility and other advantages. Under ultraviolet irradiation, it can quickly harden and produce strong adhesive properties. After curing The adhesive layer is tough, high strength, impact resistance, vibration resistance, aging resistance and weather resistance. It can protect the solder joints on the circuit board from short circuit, enhance the tensile strength of the upper tin dots, enhance the bonding strength of the tin solder joints and the substrate, and have excellent electrical performance.

The solder joint protects the UV glue, has good adhesion to metal and plastic, good hardness, short operation time, can improve production efficiency, and is very suitable for continuous production operations.

Recommended reason:

Due to the requirement of temperature insulation of solder joints, there are only two types of silicone and UV glue. It is recommended to use UV glue, mainly for good hardness and short operation time. Organic silicone has good temperature resistance, but the curing time is long, even if the heating and curing is faster, it takes 1-2 hours, the hardness is small, and it is not recommended for normal use.